Dry Back LVT

Dry Back LVT – Combine Elegance with Function!

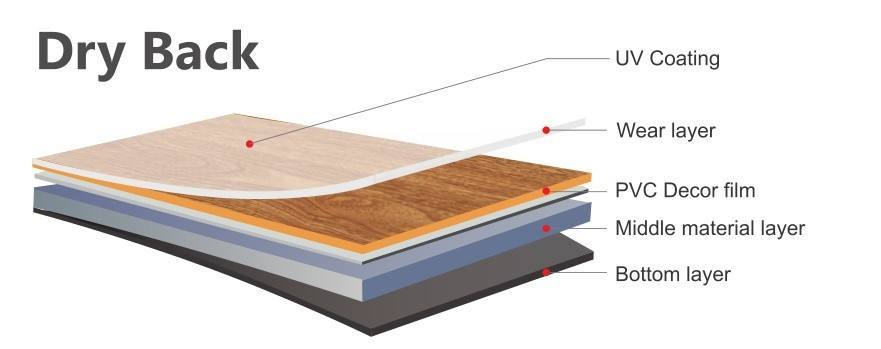

Zomei Flooring Dry Back LVT is an easy to cut, easy to fit, and easy to clean flooring designed for permanent installations on a new or existing subfloor.

With a slip resistant coating ranking of R10, Dry Back LVT is an ideal solution for vinyl installation on top of an existing floor.

This LVT is directly glued to the subfloor with an underlay solution or adhesive, giving exceptional dimensional stability to the floor.

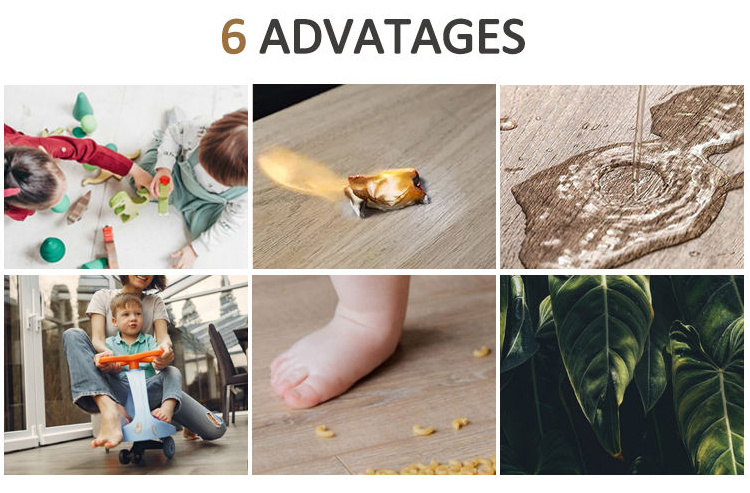

Why Dry Back LVT?

Why Dry Back LVT?

Dry Back LVT has rigid core construction capable of providing maximum stability and stain & scratch impact resistance.

It hides the sub-floor imperfections and gives the floor a finished, versatile look that merges into the overall theme of the installation site.

With vibrant designs and bold accents, Dry Back LVT is 100% water proof and abrasion resistant opening up endless location makeover possibilities.

What are the benefits of Dry Back LVT?

√ Easy to install √ Impact Resistant

√ Easy to clean √ Non-Abrasive

√ Easy to maintain √ Fade Resistant

√ Highly Durable √ Anti-Slip

√ Waterproof & Fireproof √ Anti-Static

√ Hygienic and Child Friendly

√ R10 Resistant Coating Ranking

√ Suitable for commercial places with heavy footfall

√ Approved for residential and commercial setting

How to install Dry Back LVT?

Dry Back LVT requires full spread adhesion to be installed.

You will need utility knife, adhesive, measuring tape, and carpenter square to install Dry Back LVT.

Ensure that the suitable environment has been created for Dry Back Installation.

Sort visual variation of Dry Back LVT on at least 25% of the floor and categorize visual variation piles. For LVT’s having arrows on the back, ensure that all arrows point in the same direction. This will help create a consistent blend of flooring and avoid image variations.

Determine the layout and snapping centre line of the installation area.

Spread the adhesive on to the manageable sections evenly. Take care that adhesive be applied only on the area that can be worked within the recommended working time recommended by the adhesive manufacturer.

Apply the Dry Back LVT on the area with adhesive spread. Ensure that the LVT has been cut according to the area requirements in cases where application area is less than or different in shape than the Dry Back Luxury Vinyl Tile.

How to take care of and maintain Dry Back LVT Floor?

How to take care of and maintain Dry Back LVT Floor?

√ Regularly sweep the surface grit and dust with a damp cloth or mop. Alternatively, use pH neutral cleaners to clean the LVT surface.

√ Avoid using abrasive cleaners or scouring agents to clean the LVT floor

√ Avoid moving heavy equipment, appliances or furniture across the LVT floor

√ Use chair mats at desks to avoid floor damage due to chair legs and chair casters

√ Keep felt protective pads under heavy equipment or furniture.

√ Keep doormats at entrance points. Do not use rubber backed rugs or mats as they can discolour the floor.

√ Use window coverings to protect the LVT floor from direct sunlight

√ Save some flooring boxes to be used to repair floor in cases of accidental damage.

Contact us for further details and quesries.

OUR EQUIPMENT